Watflo invention aims to slash water usage by 50%

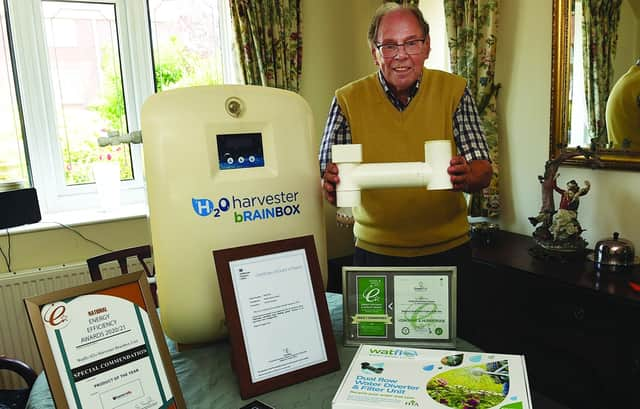

Entrepreneur Melvyn Davenport, of Wath, says his Watflo innovation, which is designed to harvest rain water and repurpose the “grey” water from showers and sinks, could cut domestic water usage by half.

If adopted across the country, he said, it could slash home water bills by 50 per cent and make waves in helping companies cut costs.

Advertisement

Hide AdAdvertisement

Hide AdThe experienced plastic moulding specialist founded a company called Melport Plastics to produce the drainpipe attachment, which would help householders filter rainwater before delivering it into a water butt.

Melvyn, a keen gardener, said after years of research and development with designers and technicians, including experts at Sheffield Hallam University, the product was ready for market.

He said he had contacted the government to see if they would invest in the production and rollout of the eco-friendly device but had so far had no response.

“I was hoping we could sort some kind of green deal,” Melvyn said.

Advertisement

Hide AdAdvertisement

Hide Ad“There is a shortage of water and this would save up to 50 per cent.

“I’ve written to the prime minister and Grant Shapps but had no answer.”

Melvyn said harvested water would not be suitable for drinking but it could be used to fill toilets and be used for gardening and even car-washing.

His two-part system uses a diverter pipe and a “Brainbox” computer controlling and monitoring the water flow, for which he secured patents.

Advertisement

Hide AdAdvertisement

Hide AdBy selling shares in Melport and securing business grants, Melvyn raised funds for research, development and tooling, with more than £230,000 invested so far.

He has been working with a design team at Sheffield Hallam, Rotherham firms GA Assembly and Dearne Electrical, and Huddersfield-based Kelland Tooling.Melvyn has been provided with premises by Dearne Electrical to manufacture his first batch of products and while he said it was not yet set up for a large-scale production operation, he was keen to hear from an investor as “within a couple of months, we could be manufacturing 100 a week”.

Melvyn added: “It could go round the world.”